- Home

- Products

- Worm Gear Shaft Milling Machine

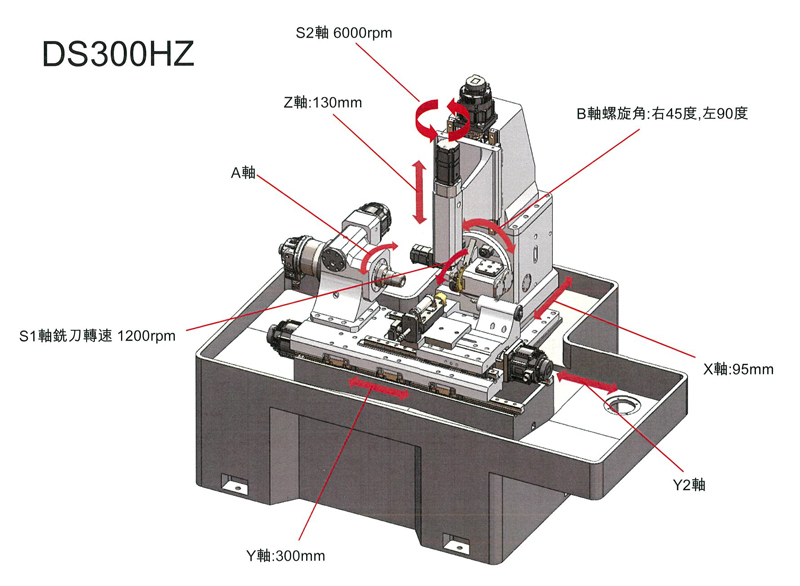

- New Product: DS-300HZ

New Product: DS-300HZ

Machine Features

- For components with a module below 3, steel forming milling cutters are used for faster cutting. Additionally, mechanical arms can be employed to address labor shortage in high-volume production scenarios.

- Thread milling.

- Sharp edge removing.

- Keyway machining.

- Industry applications: screws for the automotive industry, brush screws, electric massage chair screws, scooter screws, sun tracking systems, worm gears, and other related components.

Machine Specifications

| CAPACITY | |

|---|---|

| Range of module | M0.25 - M3 |

| Degrees of indexing | 360° |

| Max. cutting length | 300mm |

| Max. cutting diameter | 40mm |

| Max. tool dia. (hole * Keyway) | 110* 25.4* 6.35 mm |

| Helical angle | R.H.45°, L.H. 90° |

| Workpiece clamping method | collet type |

| Tailstock method | Servomotor |

| Number of simultaneously moving shaft | 8‐Axis simultaneous processing |

| SPEED | |

|---|---|

| Max. speed of X‐axis (for. / back.) | 5000 mm/min |

| Max. speed of Y‐axis (right / left) | 5000 mm/min |

| Max. speed of Y2‐axis (right / left) | 5000 mm/min |

| Max. speed of A‐axis (chuck) | 6000 mm/min |

| Max. speed of B‐axis (Cutter tilting axis) | 300 mm/min |

| Max. speed of Z‐axis (up / down) | 5000 mm/min |

| Max. angular speed of S1‐axis cutter | 1500 rpm |

| Max. angular speed of S2‐axis cutter | 6000 rpm |

| Max. speed of cutting stroke | 5000 mm/min |

| ACCURACY | |

|---|---|

| Perpendicularity of machining | ± 5μm / 100mm |

| Workpiece precision | 3~4 levels |

| Workpiece surface quality (μm) | Ra 0.8 |

| MOTOR | |

|---|---|

| X axis motor | 1.8KW / 11.5NM |

| Y axis motor | 1.8KW / 11.5NM |

| Y2 axis motor | 1.3KW / 8.34NM |

| A axis motor | 0.85KW / 5.39NM |

| B axis motor (Cutter tilting axis) | 0.4KW / 1.27NM |

| Z axis motor | 0.85KW / 5.39NM |

| S1 axis cutter motor | 4.4KW / 28.4NM |

| S2 axis cutter motor | 1KW / 3.18NM |

| Cutting fluid motor | 1.5 KW (2HP) |

| Hydraulic motor | 0.75 KW (1HP) |

| Oil controller | 0.15 KW |

| Cutting fluid separation tank | 0.1 KW (1/8HP) |

| mist collector | 0.25 KW |

| Chip conveyor | 40 W |

| MISCELLANEOUS | |

|---|---|

| Total power (KW) | 18 KW |

| Machine dimensions | 206* 155* 198 CM |

| positioning space dimensions | 211* 212* 243 CM |

| Packing dimensions | 236* 232* 228 CM |

Machine Specifications

Machine Structures

- For components with a module below 3, steel forming milling cutters are used for faster cutting. Additionally, mechanical arms can be employed to address labor shortage in high-volume production scenarios.

- Thread milling.

- Sharp edge removing.

- Keyway machining.

- Industry applications: screws for the automotive industry, brush screws, electric massage chair screws, scooter screws, sun tracking systems, worm gears, and other related components.